How General Assembly Services Streamline Production and Save Costs

Manufacturing businesses constantly seek ways to optimize production while keeping costs in check, and one of the most effective solutions is leveraging general assembly services. These services provide a dedicated workforce to efficiently assemble components using standardized processes, optimized workflows, and automation where possible. By outsourcing assembly, companies can reduce labor time, minimize waste, and accelerate production cycles—ultimately lowering overall production costs.

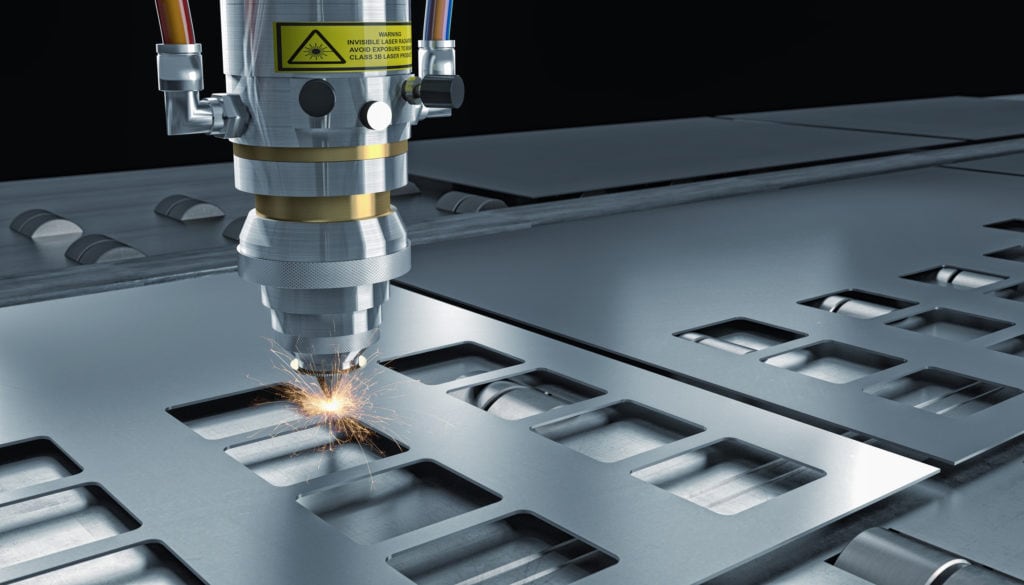

At Smucker Laser Cutting and Metal Manufacturing, we integrate precision laser cutting and advanced metal fabrication into general assembly services, offering clients seamless production workflows that enhance efficiency and cut costs even further.

Cost Savings and Efficiency through General Assembly

Specialization and Division of Labor

A key advantage of general assembly services is the division of labor. By assigning specific tasks to dedicated workers on an assembly line, the process becomes highly efficient, reducing errors and increasing productivity. Workers become skilled in their specific roles, enhancing speed and precision.

At Smucker Laser Cutting and Metal Manufacturing, our precision-cut components streamline assembly, ensuring seamless integration and reducing errors that might arise from inconsistent parts.

Optimized Workflows

Expert assembly providers design streamlined workflows that minimize unnecessary movements and waiting times. This ensures a smooth flow of components throughout the assembly process, reducing downtime and increasing throughput.

With our laser-cutting technology, we help businesses optimize assembly workflows by delivering components that fit precisely, reducing delays caused by adjustments and rework.

Automation Integration

Many contract assembly providers integrate robotics and automated systems to handle repetitive tasks, significantly reducing labor costs while improving precision. Automation also ensures consistent product quality and minimizes human errors.

Smucker Laser Cutting and Metal Manufacturing employs state-of-the-art laser cutting and metal fabrication automation, reducing material waste and ensuring superior precision in manufacturing processes.

Design for Assembly

Collaboration with product designers ensures that components are designed for easy assembly, reducing the need for complex tooling and labor-intensive processes. This results in faster production cycles and lower assembly costs.

Our team at Smucker Laser Cutting works closely with manufacturers to ensure their components are designed for efficiency, eliminating unnecessary complexities in the assembly phase.

Lean Manufacturing Principles

Many outsourced assembly providers implement lean manufacturing principles such as:

- Just-in-time (JIT) inventory management to reduce excess stock and storage costs.

- Continuous improvement practices to identify and eliminate inefficiencies in production.

With our precision manufacturing approach, Smucker Laser Cutting helps clients reduce excess material waste and improve production efficiency.

Reducing Overhead Costs through Outsourced General Assembly

By outsourcing assembly, companies eliminate the need for maintaining an in-house assembly team, cutting expenses related to hiring, training, payroll, and facility management.

At Smucker Laser Cutting, we further enhance cost savings by providing fabrication and assembly services under one roof, eliminating unnecessary third-party costs and logistics expenses.

Focus on Core Operations

Outsourcing general assembly services allows businesses to focus on their core competencies. Instead of diverting time and resources to assembly tasks, they can concentrate on:

- Product innovation and development

- Marketing and brand positioning

- Sales and customer relationships

- Expanding into new markets

By delegating assembly to specialized providers, businesses can enhance efficiency and profitability without compromising production quality. Smucker Laser Cutting and Metal Manufacturing offers a full-service approach, allowing businesses to focus on their strategic goals while we handle precise fabrication and assembly.

Streamlining Logistics and Shipping through General Assembly

Direct-to-Customer Shipping

Many assembly service providers offer end-to-end solutions, including packaging, warehousing, and direct-to-customer shipping. This eliminates the need for additional handling, reducing shipping costs and lead times.

At Smucker Laser Cutting, we streamline production, assembly, and distribution for clients by providing components that fit seamlessly into existing supply chains, minimizing delays and inefficiencies.

Inventory Management

Outsourced assembly partners often provide inventory tracking and management services, ensuring just-in-time delivery of finished products. This helps manufacturers reduce storage costs and avoid overproduction.

Our fabrication expertise enables Smucker Laser Cutting to provide inventory solutions that align with lean manufacturing principles, further reducing waste and increasing efficiency.

Custom Packaging Solutions

Many general assembly providers offer customized packaging solutions, ensuring products reach customers in ready-to-sell condition, reducing damage risks and enhancing brand presentation.

At Smucker Laser Cutting, our attention to detail ensures that fabricated components and assembled products are packaged efficiently for protection and ease of handling.

Scalability and Flexibility in General Assembly

Adapting to Demand Fluctuations

One of the greatest advantages of contract assembly is its scalability. Businesses can quickly scale production up or down based on demand without investing in additional infrastructure or workforce.

With Smucker Laser Cutting, manufacturers gain a flexible production partner that can quickly adapt to high-demand cycles without compromising quality or delivery speed.

Rapid Market Entry

Outsourcing assembly allows companies to bring new products to market faster without worrying about setting up complex production facilities.

With our advanced laser-cutting capabilities, businesses can develop prototypes and scale to production quickly.

Cost-Efficient Expansion

Instead of investing in expensive machinery and additional labor, companies can rely on third-party assembly partners to increase production capacity cost-effectively.

At Smucker Laser Cutting, we help businesses expand cost-effectively by offering integrated fabrication, assembly, and finishing services.

Why Choose Smucker Laser Cutting And Metal Fabrication

Outsourcing general assembly services provides businesses with a cost-effective, efficient, and scalable solution to streamline production. By leveraging specialized labor, automation, and optimized workflows, companies can reduce overhead costs, increase production capacity, and focus on innovation.

At Smucker Laser Cutting and Metal Manufacturing, we take assembly solutions a step further by offering precision-cut components, efficient assembly workflows, and integrated logistics services—all under one roof. Whether you’re in automotive, electronics, consumer goods, or medical device manufacturing, partnering with us can give you a competitive edge in production efficiency and cost savings.

Looking for a reliable general assembly partner to help you optimize production and reduce costs? Contact Smucker Laser Cutting and Metal Manufacturing today to explore customized fabrication and assembly solutions tailored to your business needs!