Laser Cutting Services

At Smucker Laser Cutting and Metal Fabrication, we specialize in providing top-notch laser cutting services to a diverse range of industries, including OEMs, military, transportation, and recreational industries. We have laser machines and a full line of fabrication equipment to handle different jobs, from prototyping to long production runs. CAD system integration enables us to fabricate laser-cut parts from customer-provided blueprints, CAD files, drawings, or sample pieces in short lead times. We offer unparalleled precision, efficiency, and flexibility to meet all your laser-cutting needs.

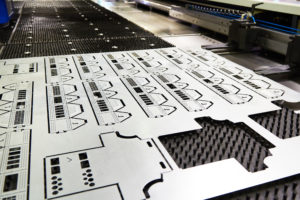

We use CAD/CAM design programs to cut parts from materials such as aluminum, stainless steel, and mild steel. Our laser-cutting machines offer several advantages, including high repeatability, guaranteed part reproduction, and a narrow kerf. The non-contact cutting method also enables us to fabricate parts with minimal distortion and consistent, burr-free cuts, reducing the need for subsequent finishing operations. Our laser cutters can process metal sheets up to 5′ x 10′ in size. As no tooling is required, these laser cutting services are economical and delay-free options for customers.

What is Laser Cutting?

Laser cutting is a precise and versatile metal cutting process that utilizes a high-powered laser beam to cut through various materials. It directs the laser beam onto the material surface, melting or vaporizing it along the designated cutting path. Laser cutting offers several advantages, including high precision, speed, versatility, and the ability to cut intricate shapes and patterns with minimal material wastage. It is widely used in manufacturing, aerospace, automotive, electronics, and other industries for producing precise and complex metal components with exceptional accuracy and quality. Smucker Laser Cutting and Metal Fabrication commonly services industries, including OEMs, military, transportation, and recreational industries.

Our Laser Cutting Process

Advanced Laser Technology:

Our cutting-edge Fiber Laser and CO2 systems and flying optics technology enable us to deliver exceptional cutting precision and speed

Extensive Material Capability:

We are proficient in cutting various materials, including aluminum, steel, stainless steel, mild steel, ferrous metals, and non-ferrous metals, with maximum cutting thicknesses of up to 1/2″ for aluminum, 1 1/4″ for stainless steel, 1 1/4″ for mild steel, 3/8″ for brass, and 3/8″ for copper.

High Repeatability and Part Reproduction:

With CAD/CAM design programs integrated into our workflow, we ensure high repeatability and guaranteed part reproduction, allowing consistent quality across all production runs.

Advantages of Our Laser Cutting Services

Narrow Kerf and Minimal Distortion:

Our laser-cutting machines produce narrow kerfs, reducing material wastage and distortion. This ensures precise cuts and minimizes the need for additional finishing operations.

Burr-Free Cuts:

The non-contact cutting method employed by our laser machines ensures burr-free cuts, maintaining the integrity and aesthetics of the finished parts.

Economical and Delay-Free Options:

As no tooling is required, our laser cutting services offer economical and delay-free solutions for customers, making them ideal for prototyping and large-scale production.

Laser Cutting With Smucker Laser Cutting + Metal Fabrication

Our laser-cutting services combine cutting-edge technology, extensive material capabilities, and a commitment to precision and quality. Whether you need prototypes or large-scale production runs, our team is dedicated to delivering exceptional results that meet your exact specifications and requirements. Contact us today to learn more about how our laser-cutting services can benefit your projects.

Machine and Specifications

- Laser Type

Fiber & CO2

- Cutting Axis

3 Axis

- Materials

Aluminum

Steel

Stainless Steel

Mild Steel

Ferrous Metals

Non Ferrous Metals

Heavy Plate

Thin Metal

Copper

Brass

- Maximum Cutting Thickness

Aluminum: 1/2″ max

Stainless Steel: 1 1/4″ max

Mild Steel: 1 1/4″ max

Brass: 3/8″ max

Copper: 3/8″ max

- Maximum Cutting Length

10 ft

- Maximum Cutting Width

5 ft

- Maximum Output Power

10,000W

- Tolerance

+/-0.005″

- Volume

Large or small quantities

Prototyping available

- Delivery/Lead Time

Quick Turn around and short lead times

- Equipment List

Trumpf 3030 – 10,000 watt Fiber Laser

Trumpf 3030 – 5000 watt CO2 Laser

Trumpf 2030 – 4000 watt Fiber Laser

- Automation

Automatic Pallet

Changer Fully programmable focus

Vacuum lift

- Drawing Types Accepted

.dxf files preferred (all CAD accepted)

SolidWorks Files

Drawings

Blueprints

Sample pieces

Additional Services and Capabilities

- Secondary Operations

Forming

Powder Coating

Fabrication

Machining

Welding

- Production Focus

Contract Manufacturing

Fabrication

OEM Private Label products

- Industry Focus

Agriculture

Construction

Architectural

Aerospace

Automotive

Building

Electronic

Medical

Semiconductor